|

|

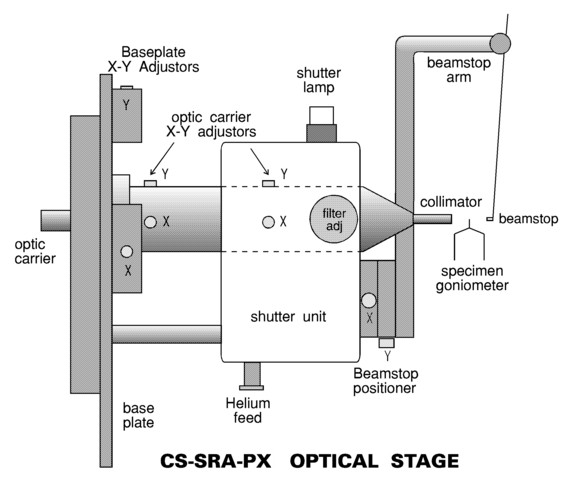

SRA Optical Stage: High-precision micrometer positioners for optic, integral rotary shutter mechanism and safety interlocks, adjustable Kb filtering from 0 to 20 µm. No-filter position allows rapid specimen quality survey and data collection from weak diffractors for which Kb intensity is negligible or readily resolved. X-Y adjustable "microbeamstop" for minimum exposed coldstream beam-path between exit collimator and beamstop (12mm). Stage replaces standard camera-shutter to permit maximum solid-angle collection from source and features helium beampath from coldstream up to generator high-vacuum window.

Beam diameter at crystal: 150 µm FW

Beam divergence: 0.15° Full width above background

Monochromaticity: 97% Ka, <1% Kb (minimum filtering)

Cell-edge resolution: 800Å at 350 mm camera length

Beam focus position: 50mm past crystal, 300mm from anode target position

Intensity: 20x collimation [with filter present]

Rotating anode X-ray generator, Cu anode, 0.1 x 1.0mm target focus cup

Specimen oscillation stage with lateral translation (oscillation axis 250mm from anode target, at 6° take-off angle)

Specimen telescope with crosshairs/graticule

Helium feed for optics (recommended for 20% added flux - optic does not tarnish)

Relative intensities for the HRPX system fitted to the source shown in each case

Optical system Configuration HRPX rel. I HRPX rel. SNR MSC "Green" optics on rotating anode* 5kW, 0.3x3mm-target 4x >10x MSC "Green" optics on FR-D® or FR-E® 0.1x1mm-target 3x >10x MSC "Green" optics on FR-E® 0.07x0.7mm-target 3x >10x MSC "Green" optics on MicroMax007® 800W 3x >10x Notes: Intensity is flux per unit area at specimen position. (*) HRPX system used with 0.1x1mm target at 1kW.

"rel SNR" is beam intensity / background scatter at equivalent angles - [How is this defined?]

"MicroMax", "FR-D", "FR-E" are registered trademarks of Rigaku corp.

Clearances: Oscillation axis to beamstop positioner: 22mm; Depth of shutter unit below beam axis: 86mm

Base plate: Form-factor of integral base plate is matched to specified make and model of X-ray generator. This ensures minimal optical alignment effort at installation.

Shutter unit: High-speed longlife rotary solenoid. Optical shutter position interlocks. Replaces standard camera/rotary shutter fitted to anode tower. Connection to existing X-ray generator interlocks and shutter controller is supported by the unit.

Alignment: Optical alignment upon installation is achieved by monitoring beam intensity at the specimen position (requires radiation meter) whilst adjusting optic position. Intensity max. corresponds with optimal alignment. Trim alignment (e.g. after anode assembly refit) is facilitated by fine adjustment verniers on X-Y adjusters.

Exit collimator: The system is fitted with a fixed 0.15mm exit collimator which incorporates multiple lead and platinum apertures as scatter arrestors. Optic carrier is factory pre-aligned with exit collimator prior to shipment.

Beamstop: 1.0mm diameter micro-beamstop is positioned just outside the coldstream to minimise X-ray scatter. The beamstop extension arm swivels to allow easy access to the goniometer head for specimen placement and removal.

(c) copyright AXCO 2004